Call Us: 555-555-1234

Items For Sale

|

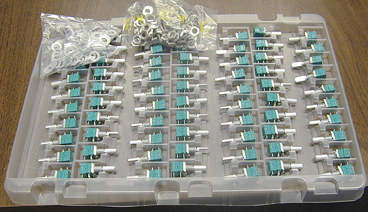

Rotary enc mom push 9mm 30 detent |

|

RK09710ELC07 |

70units/tray

$130.00/tray of 70 units

Call 905-871-0733 for pricing

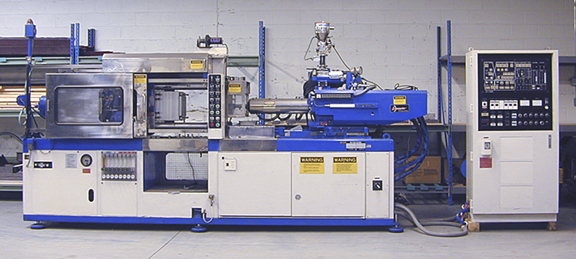

Manufacture Your Own Electronics

Risk

Free Opportunity to buy a Universal GSM Pick and

Place machine

Risk

Free Opportunity to buy a Universal GSM Pick and

Place machine

If you are building boards by hand or paying

an assembly house big setup costs and

outrageous prices and then suffering long

delivery times then you really need your own

pick and place machine. Or if you already

own a low cost light duty machine and are

tired of adjusting parts by hand, hand

placing the parts it won’t handle or just

fed up trying to make it work then you need

a real machine not a toy. If you buy the

right machine it will make high quality

assemblies saving you time and making money.

You can take control of your manufacturing

process and build boards when you need them

instead of building large batches to get a

better price. While there are several low

cost, light duty pick and place machines

available they don’t work very well. Never

the less first time buyers constrained by a

modest budget are lured by the low price

without a clear understanding of what they

are getting or what they really need.

Perhaps you are willing to compromise

performance, accuracy, reliability and

versatility to get a low price but you

don’t have to.

Buy a Real Machine not a Toy

Universal Instruments headquartered in

Binghamton NY is the largest domestic

manufacturer of pick and place machines.

They are famous for their versatile model

GSM pick and place machine. Produced in

greater numbers than any other it is the

most successful machine of all time. When

other machines were specialized to place a

narrow range of parts the GSM would place

almost anything. Parts as small as 0201’s

(.010 x .020 inches) or connectors beyond 5

inches long are all within range. Every part

goes down with flawless precision. The GSM

is designed to perform unattended in

continuous high volume production it is not

to be compared with limited light duty

machines that struggle to do anything well.

This machine originally sold in systems

costing ½ million dollars or more. Customers

expected a lot for that kind of investment

and they got it. Day after day this machine

would deliver a continuous stream of

flawlessly assembled electronics.

Versatile, reliable and precise the GSM is

an ideal machine for general purpose use.

A

novice buying any pick and place machine

takes on a great risk. A dusty machine

sitting in a warehouse could be missing

parts or have problems that cost a fortune

to repair. Many machines are retired only

when beyond economical repair so look out.

If you can’t see it run you shouldn’t

consider buying it. How will that machine

handle your current and future requirements?

How will you learn how to use that machine?

How long will that take? Any machine worth

having will have software that is feature

rich and capable but not simple, obvious or

self explanatory. Learning it alone by

reading the manuals while not impossible is

certainly impractical. Don’t overlook the

challenge and true cost of mastering the

software.

A

novice buying any pick and place machine

takes on a great risk. A dusty machine

sitting in a warehouse could be missing

parts or have problems that cost a fortune

to repair. Many machines are retired only

when beyond economical repair so look out.

If you can’t see it run you shouldn’t

consider buying it. How will that machine

handle your current and future requirements?

How will you learn how to use that machine?

How long will that take? Any machine worth

having will have software that is feature

rich and capable but not simple, obvious or

self explanatory. Learning it alone by

reading the manuals while not impossible is

certainly impractical. Don’t overlook the

challenge and true cost of mastering the

software.A Truly Unique Opportunity

I am offering you the opportunity I wish I

had when I decided to get into pick and

place machines. The machine we offer for

sale is not under a tarp or in a warehouse.

It is fully functional in our working

production line linked by conveyor to

similar machines. It won’t be moved until

you see it work and buy it. But before we

move it we will provide training for your

personnel to setup your first board. So when

you install the machine in your facility it

will be ready to run ! Unlike other eBay

machines you are buying a risk

free fully

functional package.

A second machine is part of the package.

While the first machine is fully functional

in beautiful condition, the second is ugly

but full of valuable spare parts.

So What’s the Difference?

So what’s different about this machine? The

sophistication of design, the quality of

engineering, versatility and the attention

to detail distinguish this machine among the

low cost light duty machines built off shore

or in someone’s garage. This machine’s

software developed to serve diverse

professional needs is highly refined and

vastly superior to light duty machines. The

machine is built on a strong rigid frame. It

axis’s are driven by closed loop servo

motors with high precision ball lead screws.

The precision of each axis is guaranteed by

1 micron resolution Heidenhain linear

encoders. The value of precision is that you

can place parts directly from CAD data first

time – every time. But now precision is more

important than ever because the new lead

free solder alloys don’t self center

misplaced parts like the old lead solder

did. Low yields and widespread re-work costs

are the reward for poor accuracy.

The head on this machine is the most

versatile and highest precision

multi-spindle that Universal offers. It has

4 spindles and will pick up 4 parts at once

to save time. Each trip to the board will

deliver 4 parts instead of just one. Each

spindle supports a wide variety of nozzles

to handle virtually any type of part. Of

course all motion on the head is closed loop

servo controlled.

Great Vision is the Key to Versatility

Even with a great head and precise

positioning system you still need an

excellent machine vision system to

accurately place parts. Vision processing

software is tremendously challenging and

takes years to perfect so this is where

lesser machines always fall short. Without

great vision nothing works very well. This

machine has two upward looking cameras with

sophisticated lighting systems designed

specifically to illuminate parts. Two

cameras minimize the travel time for any

component, and allow for two different

magnification levels if desired. All

components go over the camera to be

measured. Parts as large as 1.3 inches can

be imaged in one frame, but the machine is

not limited to just one frame, and can

utilize multiple images for large parts. Parts

as small as 0402 are handled by the

currently installed cameras but 0201 parts

require a higher resolution camera. I have

hi-res cameras if you need one. The

versatility of the vision system really

determines the capability of the machine.

This vision system is very versatile and

captures component images while in motion to

save time. Not only does it recognize and

analyze every imaginable standard part type,

it has exotic pattern recognition algorithms

so the user can program it for anything

else. Then in the blink of an eye it

provides an exact linear and rotational

correction to place the part perfectly every

time. It can even find flaws like bent leads

on a QFP package or missing solder balls on

a BGA. You don’t want to trouble shoot or

throw out a complex board just because of a

bent pin or one bad solder connection. It’s

the versatility of the vision that lets you

place headers, DB connectors, USB

connectors, SD card sockets and countless

others in addition to all the usual types.

Remember this machine was designed to run in

an automated production line producing high

quality assemblies around the clock. Hand

adjusted parts would be out of the question

and even a 99.9% success rate would be

woefully inadequate.

While most of your placements can be

achieved with about 4 nozzle types there are

over 700 different nozzle types available.

Most pickup with vacuum but some (called

grippers) actually grip the parts with

little fingers to handle parts without flat

surfaces. The nozzle interface is easy to

replicate so you even make your own custom

nozzles.

You can Place ½ Million Parts per Week

This machine is rated at 5000 components per

hour and will easily achieve that. It’s

based on simultaneously picking 4 components

and placing them on a 16” x 18” board. With

a smaller board you could do even better.

Even if you average only 3000 cph you can

place ½ million parts per week. That easily

meets the needs of many manufacturers.

Unlike low end machines you can increase

throughput and expand feeder capacity by

adding additional machines joined by

conveyor or move up to versions of the same

machine that use the same feeders and same

software with dual beams and heads for

10,000 cph or seven spindle high speed heads

for 20,000 cph.

The machine’s versatility in feeders is

unmatched. It can handle 64 feeders that may

be organized in quick change modules of 16.

There are feeders for almost every

imaginable part. Tape feeders from 8mm to

120mm are available as well as tube and tray

solutions. Feeders are widely available on

the used market and surprisingly

inexpensive.

We need room to expand our GSM production

line and have one machine for sale.

Our GSM machines do an amazing job for us,

they’ll do the same for you.

Asking: $20,000.00

Call John: 905 871 0733

Call John: 905 871 0733

Specifications

The GSM pick and place machine is fully

specified by a 96 page document. Contact me

if you’d like a copy. A few of the high

points follow.

Board size: 18

x 20 inches normal 20

x 32 inches special

Feeder slots: 64

Feeder size range: 8mm

to 120mm

Placement rate: 4500

cph or more

Size: Width:

66 Length:

86 inches

Travel: X

axis: 28.64 inches Y

axis: 42.25 inches

Weight: about

4000 lbs

Power: 230VAC 3

phase

GSM Brochure ![]() -

Click Here

-

Click Here

Great for garage, barn, hanger etc.

Works on 110

Price $3,495.00

Price $3,495.00

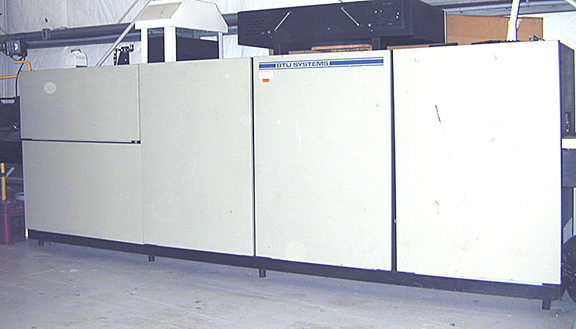

Conveyor Oven

Price $20,000.00

For Electronic Components Call 905-871-0733